Rofnel Energy Services Ltd undertakes quality and reliability services and work closely with the clients at all phases of laboratory services. Our state of the art equipment has been accredited and certified by the Department of Petroleum Resources (DPR).

We are currently involved in the following services: Water Treatment/Water Quality Analysis: This involves the analysis of basic qualities of water which includes: PH, Temperature, Turbidity, Conductivity, Resistivity, TDS, Alkalinity, SDI, DO, metals and non-metals (Chloride, Chlorine, Sulphate, Phosphate, etc.)Effluent Discharge Monitoring/Analysis: This involves analysis of water effluents from flow stations to monitor and ensure satisfactory effluents to the environment in accordance with DPR and other governmental regulations. It encompasses the analysis of metals and non- metals in addition to some of the basic qualities of water such as PH, TDS, Conductivity, etc as mentioned above.

Oilfield Waste water Analysis: These are analysis conducted on oilfield water mainly for formation identification and compatibility studies (so as to monitor scale formation). It involves metal and non-metal analysis, TDS, salinity, Temperature, pH, etc.

Soil Analysis: This is analysis conducted on soil so as to minimize and control oil spillage. It involves the analysis of metals, non-metals, Total Petroleum Hydrocarbon (TPH), Poly Aromatic Hydrocarbon (PAH), etc.

Biological Analysis: These are analysis conducted to measure and determine the presence of bacterial in any water body. It involves analysis such as Total Coli form, Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), etc.

Hydrocarbon (Oil and Gas) Compositional Analysis & PVT Studies: This is the quantification of the fractional component and impurities of natural gas or crude oil. The information from compositional analysis is very essential in oil and gas industry and it is the source of vital parameters required for efficient refining, production and many other processes. Some of these vital parameters includes: Molecular composition of gas and oil, water content, CO2 & H2S content, Gas gravity, Wobbe index, Specific gravity, Calorific value, GPM, Dew point, Compressibility factor Z, Recombined compositions, methanol in crude. Hydrocarbon Fluid Property data including initial/ current pressure, initial /current GOR, Oil API gravity, Oil /Gas Viscosity, formation Volume factor. Initial /Current reservoir fluid composition and properties which includes Oil / gas Geochemistry data C1 to C7 and isotope data.

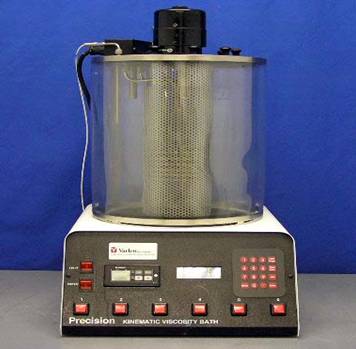

Crude Oil Assay: These analyses are conducted on crude oil for process operation at maximum efficiency. Analysis Includes: BS&W, Viscosity, Density, Flash, Cloud and pour point, TAN, TBN, RVP, Salt and Sulfur, Crude Distillation, Foaming Characteristic, etc.

Lubricating, Transformer & Hydraulic Oil Analysis: These analyses are conducted on used and un-used Lubricating samples to detect problems in hydraulics, gearboxes, pumps, engines, motors, turbines, presses, rolls and other oil-lubricated industrial machines by the use of Trivector Analyzer (Spectro 5200). The Analysis Includes: water content, Viscosity, Density, Flash, Cloud and pour point, TAN, TBN, Foaming Characteristic, Particle counts and classifications, Ferrous index, Large ferrous and large non-ferrous indication, contaminant index, Chemical Index, Dielectric constant, Transformer Oil Filtration & Regeneration, etc.

Vibration Survey, Monitoring and Analysis: These analyses are conducted on rotating equipment. We utilize CSI 9420, CSI 1230 and 01 dB-METRAVIB vibration measurement system including 01dB-Stell MOVIPACK collector and eDIAG software to perform rotating equipment vibration monitoring and Temperature analysis in hard-to-reach locations. They provide complete vibration data including overall levels, energy bands, high resolution spectra and wave forms. This goes on with 3-way collect spectra: time-based, on-alert and on-demand.

Wireline and Well Testing Services: We carefully undertake the following slickline services: Tagging T.D, Gauge Ring runs, Broach tubing/plunger installations, Bailing Sand and debris, Shifting Sleeves, Setting/pulling plugs, Setting/pulling gas lift valves, Running Tailpipes, Bottom hole pressure and Temperature Surveys, Paraffin cutting, etc. Production Well Testing & Early Production Facility (EPF), Multiphase Flow Metering, Flow back Services, Maximum Efficiency Rate (MER), Sand Detection & Quantification

Details of past projects carried out can be viewed here.![]()